laser cutting & parts processing.

We specialize in processing orders quickly and economically. Our state-of-the-art equipment and motivated team will keep you on-target or ahead of your production schedules.

efficiency matters.

AUTOMATED MATERIAL HANDLING

Our lasers are integrated with a fully automated, “lights out” loading and unloading system. This allows us to burn unattended, around the clock, at maximum efficiency, and offer you lower cost parts and expedited deliveries.

CNC LASER CUTTING

Our powerful lasers—up to 20,000 watts—produce high-quality parts in a variety of materials: up to 1" carbon steel, 1" stainless, 1" aluminum, ¼" brass, and ¼" copper on our 78¾" x 157½" cutting table. Contact us to discuss any special materials required, or leverage our inventory for rapid delivery.

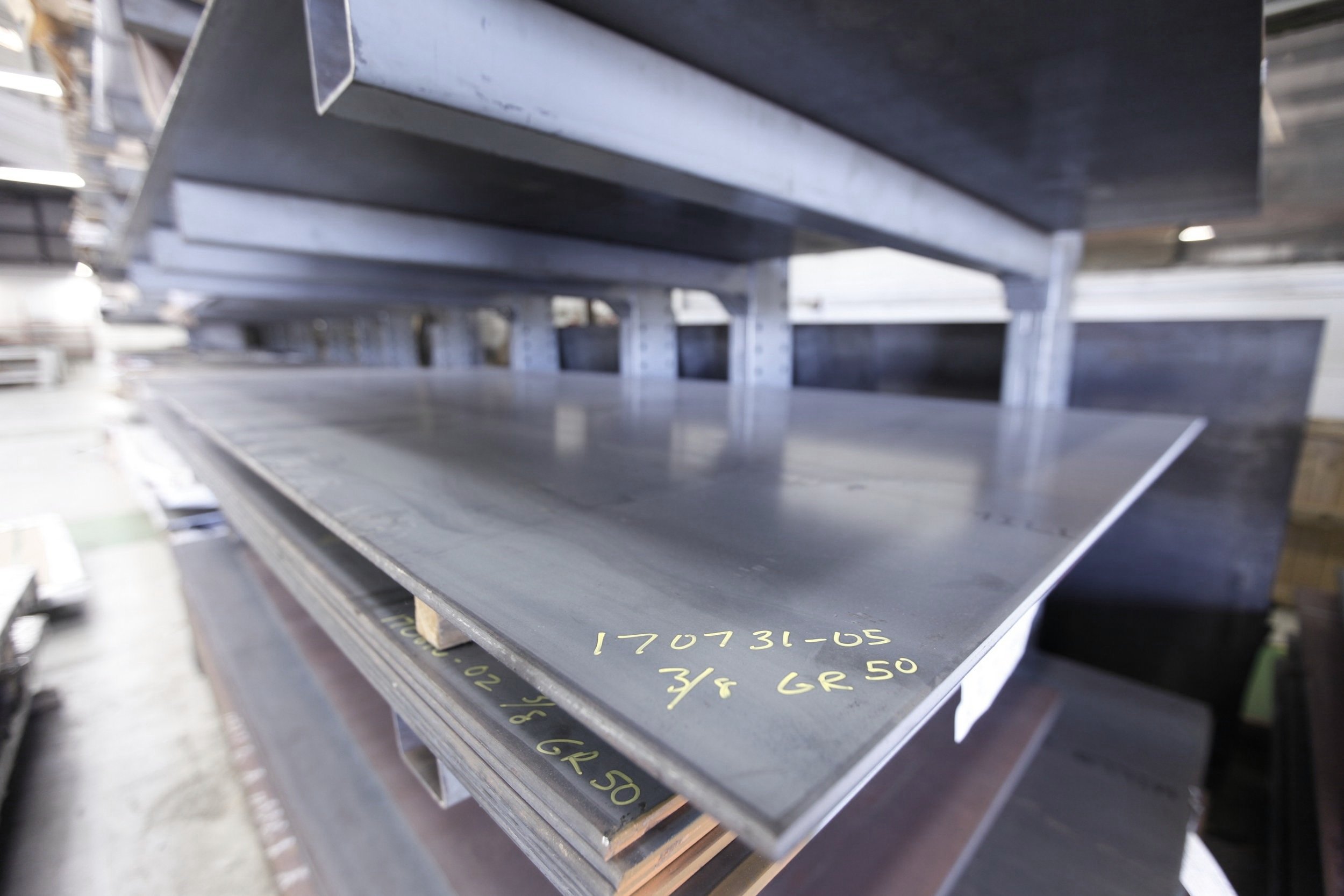

Full material inventory

We have an extensive supply of quality carbon steel, stainless, and aluminum in a variety of standard grades and thicknesses, allowing us to rapidly being production of your components.

dynamic nesting

Because we efficiently optimize sheet yield and quickly manage burn schedules on-the-fly, your parts can be processed cost effectively.

excellent parts fit-up

Our close tolerance processing methods assure an excellent fit for mating parts, including those with complex forming, welded studs, or tapped holes. Leverage the industry’s most committed team and advanced technology to reduce re-work at assembly and improve your overall product quality.

Our Services

-

Processing orders quickly and economically. Our equipment and team ensure you stay on schedule.

-

High accuracy, high-volume- results in faster production times.

-

State-of-the-art CNC mills and lathes- paired with experienced operators.

-

Experienced press brake operators have modern, advanced expertise in forming and shaping - including automatic tool clamping and CNC crowning.

-

Our experienced and adaptable team will fabricate your products from simple brackets to 10,000 lb weldments.

-

Applied after cutting, forming, or machining - delivers an assembly-ready, attractive finish.

-

Using the latest SolidWorks® software, our CAD technicians can assists you with any requirement or work with your existing files.

-

Adding value by solving all your supply chain challenges as a local, national, and global supplier.